Pharmaceutical/Chemical/New Materials

TEL:18925129293

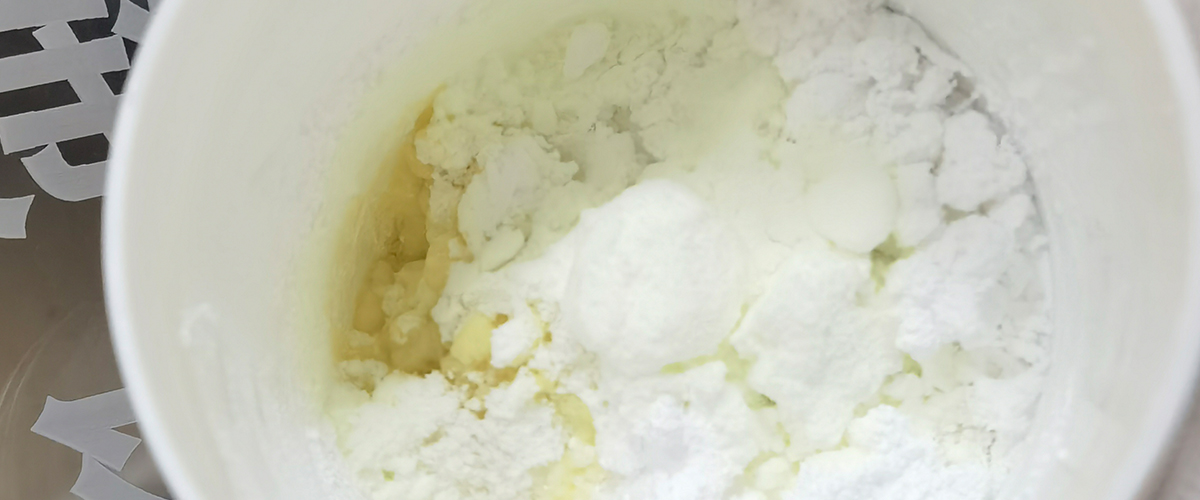

paste material

date:2023-06-01author:SIENOXSIENOX Paste Material Solution

Using Equipment: Vacuum Stirring Defoaming Machine

Equipment Model: SIE-MIX601

Sample Provider: *** University of Industry

Test Conditions:

Stirring Speed: 2000 RPM

Stirring Time: 4 minutes

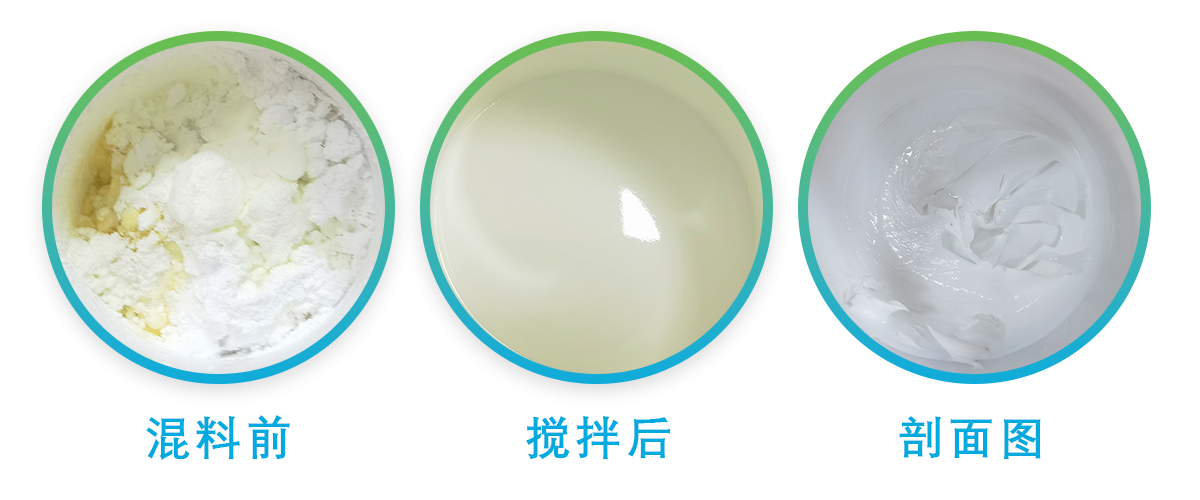

Comparison Chart of Before and After Stirring Effects

Sienox boasts over 1800 cases of powder material stirring and defoaming, available for sample testing.

Gel-like materials have extensive applications in various fields, but the persistent issue of tiny air bubbles during production and processing has been a challenge. However, with the application of SIENOX degassing machine solutions, we can easily address the bubble issues in gel-like materials, bringing numerous significant advantages to product quality and performance.

Efficient Removal of Micro Bubbles

SIENOX degassing machines utilize their unique working principles, employing centrifugal force from rotation and shear force generated by both rotation and revolution to swiftly eliminate micro bubbles in gel-like materials. This high-efficiency degassing capability ensures the smooth and uniform nature of gel-like products.

Enhanced Consistency of Product Viscosity

The uniform viscosity of gel-like materials is crucial for the user experience. The stirring action of SIENOX degassing machines thoroughly mixes the components in gel-like materials, ensuring consistency in viscosity. This not only improves the quality and reliability of the product but also enhances its competitiveness.

Improved Product Quality and Appearance

The degassing effect of SIENOX machines reduces the impact of bubbles on the performance of gel-like products, thereby enhancing product quality and stability. The degassed gel-like material is finer and smoother, improving the tactile and visual quality of the product and providing users with a better experience.

Increased Production Efficiency and Cost Savings

By using SIENOX degassing machines, the production process of gel-like materials becomes more efficient. It rapidly removes bubbles, reducing the need for subsequent corrections and saving time and resource costs. This is particularly important for enterprises engaged in batch and large-scale production.

SIENOX degassing machines bring significant advantages to the production and processing of gel-like materials. They efficiently remove microbubbles, enhance the uniformity of product viscosity, improve product quality and appearance, while also increasing production efficiency and cost savings. The exceptional performance and reliability of SIENOX degassing machines make them an ideal choice for handling gel-like materials.

Whether in the cosmetics industry, pharmaceutical sector, or other consumer goods manufacturing fields, SIENOX degassing machines play a crucial role. They not only address bubble issues in gel-like materials but also elevate product quality, increase competitiveness, and improve production efficiency while lowering costs. Through the use of SIENOX degassing machines, we can achieve higher standards in material processing and production.