Battery Slurry Mixer

TEL:18925129293

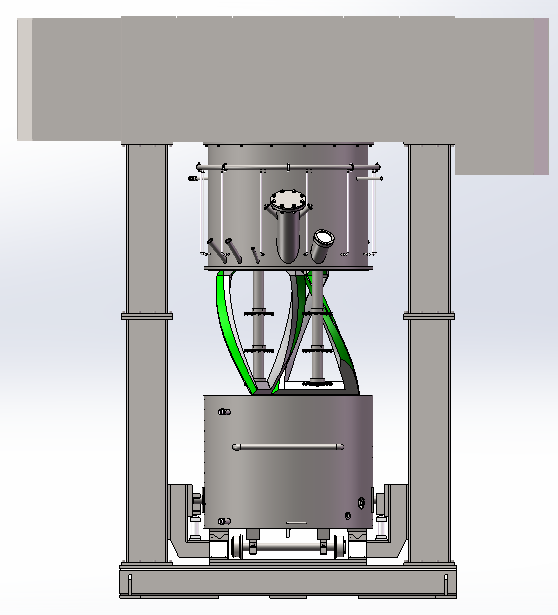

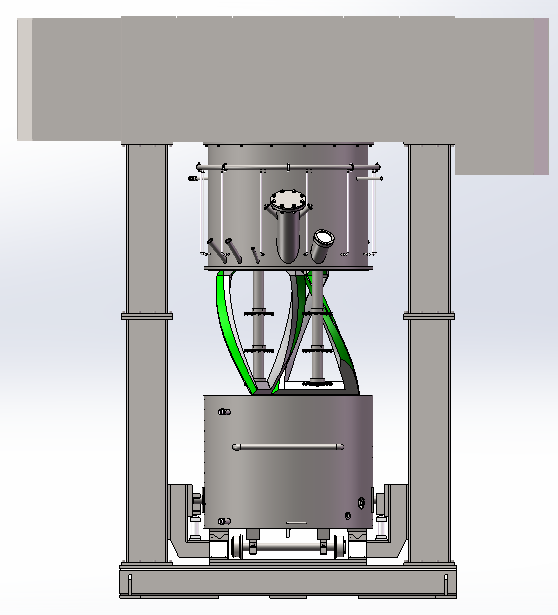

Planetary mixer SIE-ME050 lithium battery slurry mixing and defoaming machine

Vacuum mixer technology is used in the mixing process of lithium-ion battery positive and negative electrode slurry preparation, achieving mutual dispersion and full decomposition of battery slurry to achieve uniform mixing and distribution, thereby obtaining battery slurry that meets the process requirements.

Model:SIE-ME050

1. The latest design discards various flawed structures of previous old equipment, optimizes the design, and enhances stability.

2. The patented design of the mixing paddle blade is cast in one piece, CNC engraved and polished without damaging the original structure.

3. Suitable for dry process technology, reducing mixing time. The planetary gearbox adopts a vacuum-sealed integral design, and the mixing paddle and shaft are made of special steel to ensure no deformation.

4. Electrical components are all imported brands, including motors, mechanical seals, bearings, etc.

5. Comprehensive safety protection with emergency stop switches to prevent accidental operation.

6. Remote monitoring: Real-time monitoring of equipment operation status and slurry status.

Vacuum mixing technology is used in the blending process of lithium-ion battery positive and negative electrode slurry preparation, achieving mutual dispersion and full decomposition of battery slurry to achieve uniform mixing and distribution, thereby obtaining battery slurry that meets process requirements.

The mixing process exposed to air can cause contamination of the slurry and generate bubbles inside the slurry, leading to incomplete coverage of electrode materials during coating, affecting the performance and safety of battery end products. The vacuum mixer is a new type of mixing equipment that combines high vacuum and high-speed shearing dispersion, ensuring strict quality control of the mixed slurry. During the mixing process, the slurry is prone to impurity contamination, uneven dispersion, and temperature rise due to continuous movement, which can affect slurry performance. To maintain slurry characteristics during mixing, the vacuum mixer undergoes copper and iron purification treatment at the contact surface with the slurry, and the barrel wall adopts cooling water circulation technology. The high-shear disperser breaks through the original mixing technology to achieve fine dispersion of raw materials. With the increasing demand in the lithium battery market, there is a need for larger effective volume and more stable operation of vacuum mixers. Sienox, based in Guangzhou, responds to this challenge by optimizing equipment structure design and comprehensively upgrading equipment on the basis of safety and reliability. The commonly used vacuum mixer has a volume of 20 liters, and models with a capacity of 1500 liters are available for production needs, providing solutions for enterprise production concerns.

Sienox manufactures battery slurry mixers that can be compatible with common MES software or customized to develop MES software for customers.

MES (Manufacturing Execution System) is a system for collecting and integrating production information on the factory floor, providing comprehensive solutions for manufacturing information collection and analysis. MES has been industrialized in developed countries and is applied in various industries and sectors, including semiconductor, electronics, machinery, automotive, medical, food, brewing, petroleum, chemical, and metallurgy, bringing significant economic benefits to enterprises. The MES management system provided by Northern Huachuang is applied in lithium battery production lines. It connects enterprise managers, supply chain management systems (SCM), and on-site operations/production equipment, providing real-time and accurate sources of actual production data. It integrates various information from factory units (such as materials management, production management, manufacturing, quality control, and warehouse management), enabling each unit to quickly obtain the information needed for operations, thereby improving production efficiency, product quality, and customer satisfaction.

This equipment is available in multiple versions:

- The 10L and 20L versions are commonly used in research and development laboratories.

- The 200L version is suitable for small-scale production.

- The 1500L version is available for mass production.

- Customized versions tailored to the specific needs of your enterprise can also be provided.

MES (Manufacturing Execution System)

With the expansion of production lines and the development of processes, battery factories will have higher demands on the products of battery production equipment companies. However, the lithium battery production process is complex and involves many steps. Managing the work of a single process cannot control the production status of the entire production line. In the past, equipment manufacturers only provided single-function equipment to realize the battery production process, which can no longer meet the development needs of the lithium battery industry. The MES (Manufacturing Execution System) will provide managers with a comprehensive, reliable, and accurate information management platform.

The real-time information management system for lithium-ion battery production equipment monitors the entire production process from order placement to product completion by transmitting information. It guides, initiates, responds, and reports on factory activities based on timely and accurate data. By quickly responding to changing conditions and reducing non-value-added activities, it improves factory production efficiency and product quality. This real-time information system bridges the gap between the enterprise planning level and the production workshop process control level, serving as a link for integrating manufacturing process information.