Our fresh news

TEL:18925129293

The working principle and function of the centrifugal defoaming machine

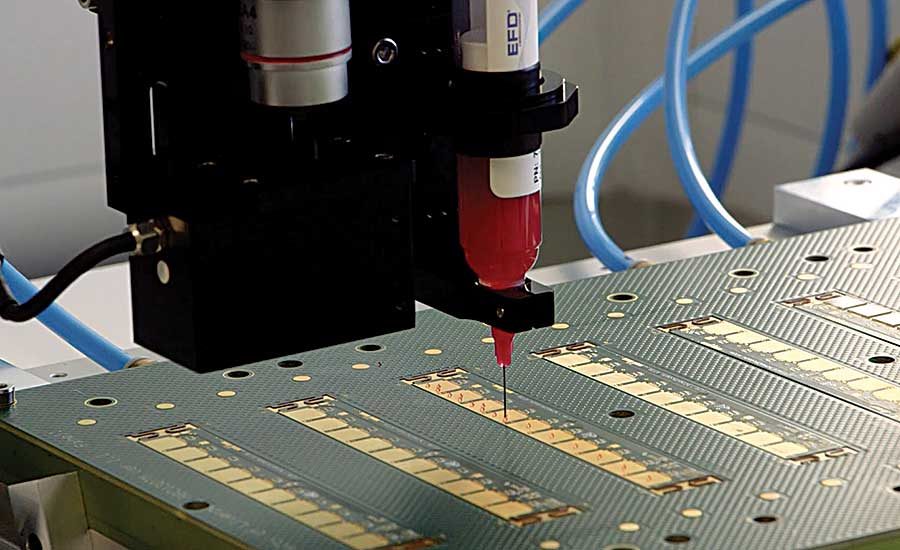

date:2023-03-24author:SIENOXThe centrifugal defoaming machine is a device used to remove bubbles from liquid materials, and its working principle is based on the action of centrifugal force. The centrifugal defoaming machine generates powerful centrifugal force by rotating the container, causing bubbles to separate from the liquid.

The main functions of the centrifugal defoaming machine are as follows:

1. Bubble Separation: The centrifugal defoaming machine, through the rotation of the container, subjects the bubbles in the liquid material to the action of centrifugal force, causing them to move towards the edges of the container. Due to the lower density of bubbles, they are separated and gathered at the top or bottom of the container, achieving the removal of bubbles.

2. Improved Product Quality: By removing bubbles from the liquid material, the centrifugal defoaming machine can enhance the quality and performance of the product. The presence of bubbles can lead to surface irregularities, uneven color, or defects such as holes. Centrifugal defoaming effectively reduces these issues, making the product more uniform and stable.

3. Increased Efficiency: The centrifugal defoaming machine can quickly and effectively remove bubbles, saving processing time. Compared to traditional defoaming methods, it has higher processing capacity and efficiency, significantly improving production efficiency and reducing costs.

The centrifugal defoaming machine finds wide applications in industries such as chemical, pharmaceutical, and food, where it can remove bubbles from liquids of various viscosities, enhancing product quality and stability.