Battery Slurry Mixer

TEL:18925129293

Ceramic slurry vacuum defoamer SIE-MIX60 planetary gravity defoamer mixer

◆ Dual cups, customizable capacity options

◆ Fixed planetary to rotation speed ratio

◆ 0-2000RPM, adjustable for experimentation based on material characteristics

◆ Vacuum/Cooling/Heating/MES system connectivity options available

Sienox is a leading manufacturer specializing in the research and production of defoaming machine equipment. We offer customizable solutions with vacuum, stirring, and temperature control functions. With advanced technology and extensive experience, we provide one-stop solutions for our customers. We offer free samples for testing and trial use, supporting defoaming and stirring in various containers such as syringes, mixing cups, and mixing tanks. Contact our customer service for detailed information!

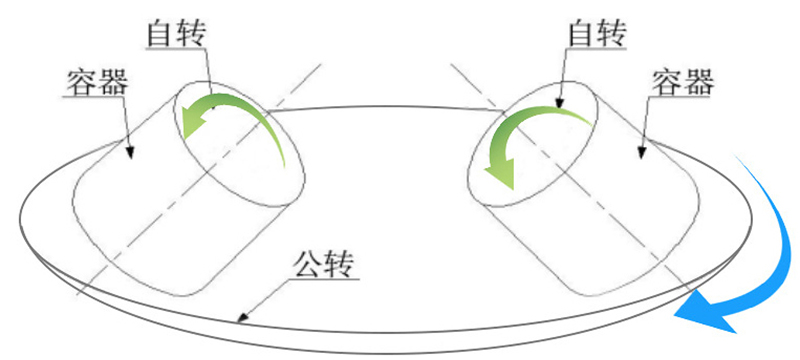

Working Principle of Vacuum Stirring Defoaming Machine:

By using centrifugal force from rotation and shear force from stirring, combined with vacuum pump extraction, tiny air bubbles in the liquid can be efficiently removed, enhancing product quality.

Sienox Defoaming Machine Product Selection Table

Model | SIE-MIX90 | SIE-MIXF1000 | SIE-MIX1000plus |

Speed(rpm) | 0-2000 | 0-2000 | 0-2000 |

Time(min) | 1-30 | 1-30 | 1-30 |

Container | Tube/Can/Cup | Tube/Can/Cup | Tube/Can/Cup |

Capacity (mL) | 0-1000 | 0-1100 | 0-1000 |

Quantity | 1*2 | 1*2 | 1*2 |

Rotation speed ratio during revolution | fixed | Adjustable | fixed |

vacuum(kpa) | -98 | -98 | -98 |

Safety lock | Yes | Yes | Yes |

Refrigeration/Heating | Optional | Optional | Optional |

SEM function | Optional | Optional | Optional |

Size(cm) | 61*56*78 | 62*61*78 | 82*61*76 |

Weight(kg) | 153 | 170 | 185 |

***The above are just typical models, and we can provide personalized solutions according to customer needs.

Industry Applications

Suitable for multiple industries including chemical, household products, medical, pharmaceutical, schools, research institutes, handicrafts, components, photovoltaics, semiconductors, and more. It addresses nano-level bubble issues and meets the needs of various fields.

Material Applications

Sienox centrifugal defoaming machines have a wide range of material applications, mainly used in high-end and precise fields such as LED, LCD, medical devices, electronic components, nanomaterials, fine chemicals, printed electronic materials, electronic packaging materials, and new energy materials. Materials include fluorescent powders, adhesives, silicone gel, silver paste, aluminum paste, binders, inks, silver nanoparticles, silver nanowires, conductive silver adhesives, insulation adhesives, battery slurries, and more. It can handle mixing of liquid to solid, liquid to liquid, and solid to solid substances.

Partial Successful Customers

***Only partial successful customer information is displayed. We need more case studies and product selection materials. Please feel free to contact us

Sienox Defoaming Machine Product Selection Table

Model | SIE-MIX90 | SIE-MIXF1000 | SIE-MIX1000plus |

Speed(rpm) | 0-2000 | 0-2000 | 0-2000 |

Time(min) | 1-30 | 1-30 | 1-30 |

Container | Tube/Can/Cup | Tube/Can/Cup | Tube/Can/Cup |

Capacity (mL) | 0-1000 | 0-1100 | 0-1000 |

Quantity | 1*2 | 1*2 | 1*2 |

Rotation speed ratio during revolution | fixed | Adjustable | fixed |

vacuum(kpa) | -98 | -98 | -98 |

Safety lock | Yes | Yes | Yes |

Refrigeration/Heating | Optional | Optional | Optional |

SEM function | Optional | Optional | Optional |

Size(cm) | 61*56*78 | 62*61*78 | 82*61*76 |

Weight(kg) | 153 | 170 | 185 |

***The above are just typical models, and we can provide personalized solutions according to customer needs.

◆ Single cup/Dual cup options available

◆ Vacuum level up to -99kPa

◆ Can store up to 100 sets of operating parameters

◆ Multiple container options: tubes, tanks, and cups

◆ Non-contact design, does not alter the chemical properties of materials

◆ Planetary to rotation speed ratio options (fixed/adjustable)

◆ 0-3000RPM, adjustable for experimentation based on material characteristics

◆ High-speed mixing and defoaming in 1 minute, uniform mixing, eliminates nano-sized bubbles

◆ Customizable capacity, standard configurations include 300mL, 500mL, 1L, 2L, 5L, and 12L

◆ Uses imported components, body made of 304 stainless steel, durable and long-lasting

◆ Vacuum/Temperature control/MES system connectivity options available

◆ Aesthetically pleasing design, durable and robust

The vacuum defoaming mixer meets the mixing and defoaming needs for volumes ranging from 0 to 1000 mL. Its adjustable planetary to rotational motion ensures clean and efficient mixing and defoaming. Customized services are offered to meet the diverse requirements of different customers. With a wide range of applications, the machine is aesthetically pleasing, durable, and robust.