Pharmaceutical/Chemical/New Materials

TEL:18925129293

Battery Slurry

date:2023-06-01author:SIENOXSIENOX Battery Slurry Material Solution

Equipment used: Vacuum Stirring Defoaming Machine

Model used: SIE-MIX80

Sample provider: Henan *** Research Institute

Test conditions:

Stirring speed: 1500 revolutions per minute

Stirring time: 3 minutes

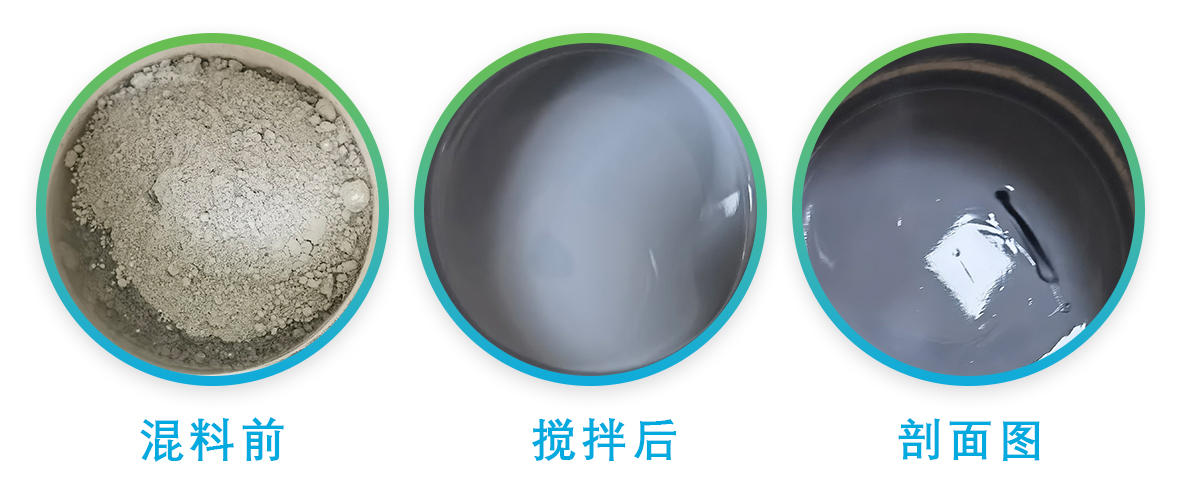

Comparison of stirring effects before and after, please refer to the image.

Sienox boasts over 1800 cases of powder material stirring and defoaming, available for sample testing.

With the continuous development of battery technology, battery slurry, as a key raw material, has a significant impact on battery performance and quality. However, during the mixing process of battery slurry, the issue of air bubbles often arises, leading to a decrease in the uniformity and quality of the slurry, subsequently affecting battery performance and stability. To address this problem, the application of the SIENOX defoaming machine has emerged as a powerful tool in the treatment of battery slurry.

The application of the SIENOX defoaming machine in battery slurry processing brings numerous benefits to customers. Firstly, it significantly improves the quality and consistency of battery slurry, reducing defects and unevenness caused by bubbles. This helps enhance battery capacity, cycle life, and safety performance, meeting the quality requirements for batteries in various application fields.

Secondly, the efficient processing capability and precise control system of the SIENOX defoaming machine make the production process of battery slurry more stable and controllable. Customers can adjust processing parameters according to their needs, achieving personalized slurry treatment and improving production efficiency and product quality.

Additionally, the automated operation and intelligent monitoring system of the defoaming machine reduce the need for manual intervention, minimizing operational errors and the impact of human factors on slurry quality. This provides customers with a convenient operating experience and a reliable production environment.

In summary, the SIENOX defoaming machine demonstrates outstanding performance and multiple benefits in its application to battery slurry. Through effective bubble removal and thorough mixing, it brings the following significant advantages to battery slurry:

1. Improved Battery Performance: The bubble removal function of the SIENOX defoaming machine ensures the purity and uniformity of battery slurry, eliminating the adverse effects of bubbles on battery performance. Bubble removal can enhance the charge-discharge efficiency and reduce internal resistance, thereby improving the energy density and power output of the battery.

2. Optimized Battery Consistency: The stirring function of the defoaming machine can thoroughly mix the components in the slurry, ensuring the even distribution of each component. This helps improve the consistency and stability of the battery, reducing performance variations during battery assembly and enhancing overall quality control.

3. Increased Production Efficiency: The efficient processing capability and automated operation of the SIENOX defoaming machine make the production process of battery slurry faster and more stable. It can handle large batches of slurry, shortening production cycles and improving production efficiency.

4. Reduced Costs and Waste: By effectively removing bubbles, the SIENOX defoaming machine reduces defects and the rate of defective products caused by bubbles. This lowers waste processing costs and increases the qualification rate and economic benefits of the products.

5. Reliable Technical Support: As a professional defoaming machine supplier, SIENOX not only provides high-quality defoaming machine products but also offers comprehensive after-sales service and technical support. Customers can receive guidance and support from a professional team, ensuring the stable operation of the defoaming machine in the application of battery slurry.

In conclusion, the application of the SIENOX defoaming machine in battery slurry brings significant benefits. Through bubble removal and thorough mixing, it improves battery performance, optimizes consistency, enhances production efficiency, and reduces costs and waste. SIENOX will continue to dedicate itself to providing innovative defoaming solutions and contributing to the development of the battery industry.