Pharmaceutical/Chemical/New Materials

TEL:18925129293

LED materials

date:2023-06-01author:SIENOXSIENOX LED Material Solution

Equipment Used: Vacuum Stirring Defoaming Machine

Model Used: SIE-MIX80

Sample Provider: *** Institute

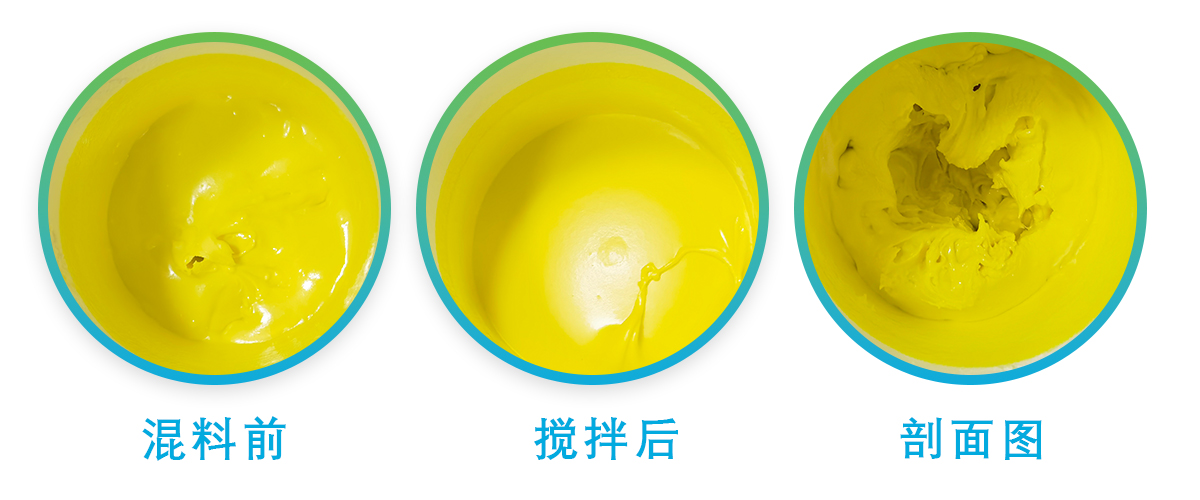

Test Conditions:

Stirring Speed: 1500 RPM

Stirring Time: 3 minutes

Comparison Chart of Before and After Stirring Effects

Sienox boasts over 1800 cases of powder material stirring and defoaming, available for sample testing.

LED raw materials are primarily used in industries such as lighting, electronics, automotive, household appliances, advertising, interior decoration, and smart grids. With the continuous advancement of LED technology and its expanding applications, the prospects for LED usage in various industries are extremely promising.

The application of the SIENOX defoaming machine in LED raw materials provides multiple benefits for LED manufacturing. It can eliminate bubbles, optimize material mixing, enhance optical performance, reduce product defects, and improve production efficiency. By choosing the SIENOX defoaming machine, LED manufacturing companies can obtain higher-quality LED products, enhance competitiveness, and meet the market demand for high-performance LEDs.

Benefits of using the SIENOX defoaming machine:

1. Bubble Elimination: Microscopic bubbles in LED raw materials can affect the quality and performance of LED chips. The defoaming machine effectively removes bubbles using centrifugal and shear forces, ensuring the purity and uniformity of raw materials. This helps improve the reliability and stability of LED chips, reducing failure rates.

2. Optimize Material Mixing: During the preparation of LED raw materials, various materials often need to be mixed. The defoaming machine provides thorough stirring and shear forces, allowing different materials to blend more effectively. This helps improve the uniformity and consistency of materials, ensuring the quality and performance of LED raw materials.

3. Enhance Optical Performance: Bubbles in LED chips can lead to a reduction in optical performance, such as light attenuation and uneven color. The application of the defoaming machine effectively removes bubbles, making LED raw materials purer and more transparent. This helps improve the light output efficiency, color temperature consistency, and color rendering of LED chips, enabling higher optical performance in LED products.

4. Reduce Product Defects: The presence of bubbles may cause defects in LED products, such as surface pores and uneven color. The defoaming machine can effectively remove bubbles, reducing the defect rate of products and improving the appearance quality and consistency of LED products.

5. Improve Production Efficiency: The defoaming machine has efficient bubble removal and mixing functions, capable of quickly processing large quantities of LED raw materials. Its efficiency and reliability contribute to improved production efficiency, reducing production time and costs.