Pharmaceutical/Chemical/New Materials

TEL:18925129293

Silver paste material

date:2023-06-01author:SIENOXSIENOX Silver Paste Material Solution

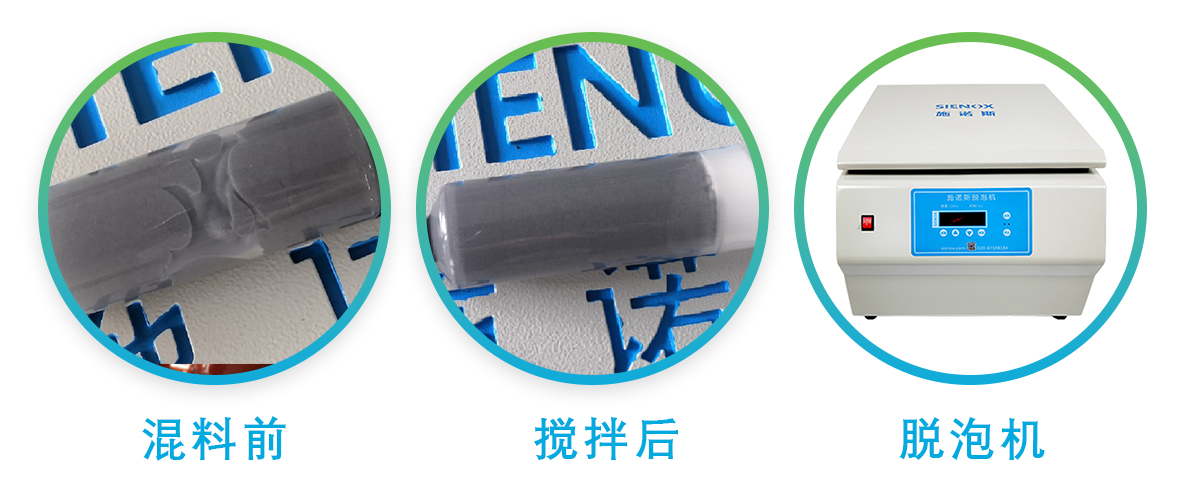

Equipment Used: Vacuum Stirring Defoaming Machine

Equipment Model: SIE-MIX90

Sample Provider: *** Institute

Test Conditions:

Stirring Speed: 1500 rpm

Stirring Time: 3 minutes

Comparison Image Before and After Stirring

Sienox boasts over 1800 cases of powder material stirring and defoaming, available for sample testing.

Silver paste material, as an essential conductive material, finds widespread applications in various industries such as electronics, photovoltaics, and printed circuit boards. To ensure the quality and performance of silver paste material, a stirring defoaming machine has become an indispensable piece of equipment.

Application and Benefits of Stirring Defoaming Machine in the Silver Paste Material Industry:

1. **Enhanced Quality Stability:**

The stirring defoaming machine effectively improves the quality stability of silver paste material by removing bubbles. Bubbles in silver paste can lead to a decrease in conductivity and may even affect the overall performance of the product. The stirring defoaming machine ensures the thorough removal of bubbles, ensuring stable quality and performance of the silver paste material.

2. **Uniform Mixing:**

During the production process of silver paste material, the stirring defoaming machine achieves uniform mixing of the material. Uniform mixing ensures even distribution of particles in the silver paste, thereby improving conductivity and adhesion performance. Additionally, uniform mixing prevents the generation of uneven colors and textures, enhancing the overall appearance quality of the product.

3. **Increased Production Efficiency:**

The stirring defoaming machine, with its efficient stirring and defoaming functions, significantly increases production efficiency. Traditional manual stirring methods require considerable time and manpower, while the stirring defoaming machine rapidly completes the mixing and defoaming process, saving production time and enhancing efficiency.

4. **Cost Reduction:**

The application of the stirring defoaming machine can reduce production costs. Firstly, it minimizes material wastage by providing better control over the usage amount, avoiding overuse or waste. Secondly, the machine improves production efficiency, reducing labor costs. Lastly, the automation of the stirring defoaming machine reduces errors and losses caused by human operations, thereby lowering maintenance and repair costs.

The stirring defoaming machine holds significant value in the silver paste material industry. By eliminating bubbles and achieving uniform mixing, the machine enhances the quality and stability of silver paste material. Simultaneously, it improves production efficiency and reduces costs. Therefore, manufacturers in the silver paste material industry should fully leverage the advantages of the stirring defoaming machine to enhance product quality and market competitiveness.