News

TEL:18925129293

The application of vacuum defoaming mixer in the lithium battery slurry industry

date:2023-07-25author:SIENOXWith the rapid development of electric vehicles and renewable energy, lithium batteries, as high-performance energy storage devices, have been widely used. In the preparation process of lithium batteries, the stirring and defoaming of battery slurry is a crucial step. In this process, vacuum defoaming mixers play an important role. This article will introduce the application of vacuum defoaming mixers in the lithium battery slurry industry.

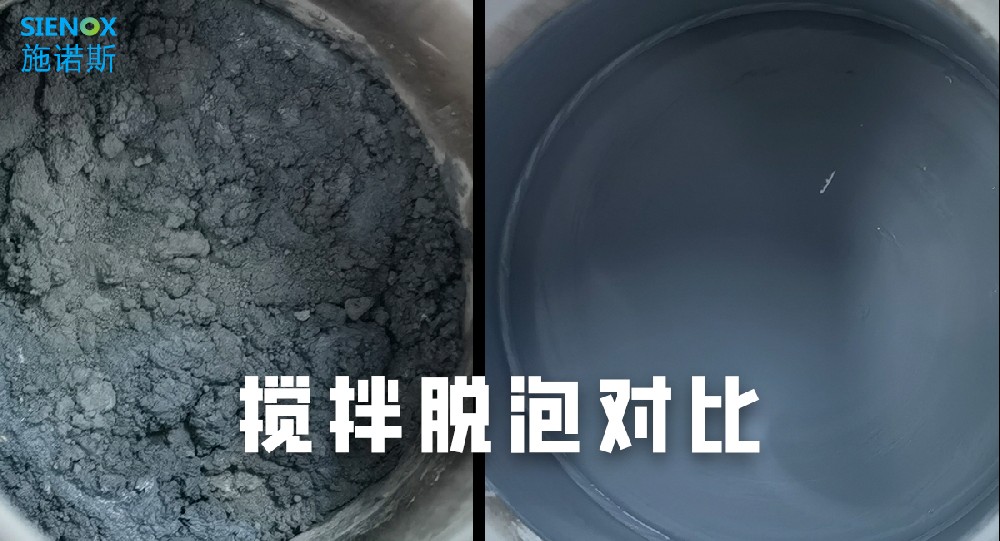

Firstly, vacuum defoaming mixers can effectively remove bubbles from lithium battery slurry. During the preparation of battery slurry, a large number of bubbles are generated due to stirring and mixing, which can decrease the quality and efficiency of the battery. Vacuum defoaming mixers create a vacuum environment to extract bubbles from the slurry, achieving rapid defoaming. This ensures the uniform internal structure of lithium batteries, thereby improving their cycle life and energy density.

Secondly, vacuum defoaming mixers have efficient and stable stirring effects. Lithium battery slurries typically have high viscosity and concentration, and traditional stirring equipment often cannot meet their stirring requirements. However, vacuum defoaming mixers, with specially designed stirring structures and blades, can effectively stir the slurry uniformly, ensuring the uniformity and stability of the battery slurry. This plays a crucial role in the performance and quality of lithium batteries.

Additionally, vacuum defoaming mixers are characterized by simple operation and safety. They employ automated control systems, enabling automatic control and monitoring of the stirring process. Operators only need to set parameters, and the machine can automatically complete the stirring and defoaming process without frequent manual intervention. Moreover, vacuum defoaming mixers have comprehensive safety devices such as overheating protection and overload protection to ensure the safety of operators and equipment.

Finally, vacuum defoaming mixers have good scalability and adaptability. With the continuous development and progress of lithium battery technology, the types and performance requirements of battery materials are constantly improving. Vacuum defoaming mixers can be adjusted and improved according to different battery materials and process requirements to meet the preparation of lithium batteries for different production scales and process requirements.

Vacuum defoaming mixers are widely used in the lithium battery slurry industry. They can quickly remove bubbles from the slurry, improve the quality and efficiency of batteries, have efficient and stable stirring effects, are easy to operate and safe, and have good scalability and adaptability. In future development, vacuum defoaming mixers will continue to play an important role in promoting further advancement and development of lithium battery preparation technology.