News

TEL:18925129293

Precautions for using a planetary mixer

date:2023-07-25author:SIENOXPlanetary mixers are commonly used stirring equipment in industries such as chemical engineering, pharmaceuticals, and electronics. They operate on the principle of planetary motion and offer efficient and stable mixing effects. However, when using a planetary mixer, it's crucial to pay attention to certain important considerations to ensure safe operation and the proper functioning of the equipment.

Safety Operation:

Before using any stirring equipment, it's essential to understand and familiarize oneself with the equipment's user manual and safety operating procedures. During operation, necessary personal protective equipment such as gloves, safety goggles, and long-sleeved clothing should be worn to prevent potential splashes and injuries.

Equipment Inspection:

Prior to each use of the planetary mixer, a thorough equipment inspection must be conducted to ensure that the equipment is in good working condition. Check whether the power supply connections are secure, all components are properly fastened, and if the machine emits any unusual odors or sounds. If any issues are identified, cease operation immediately and seek assistance from qualified personnel.

Appropriate Capacity and Speed:

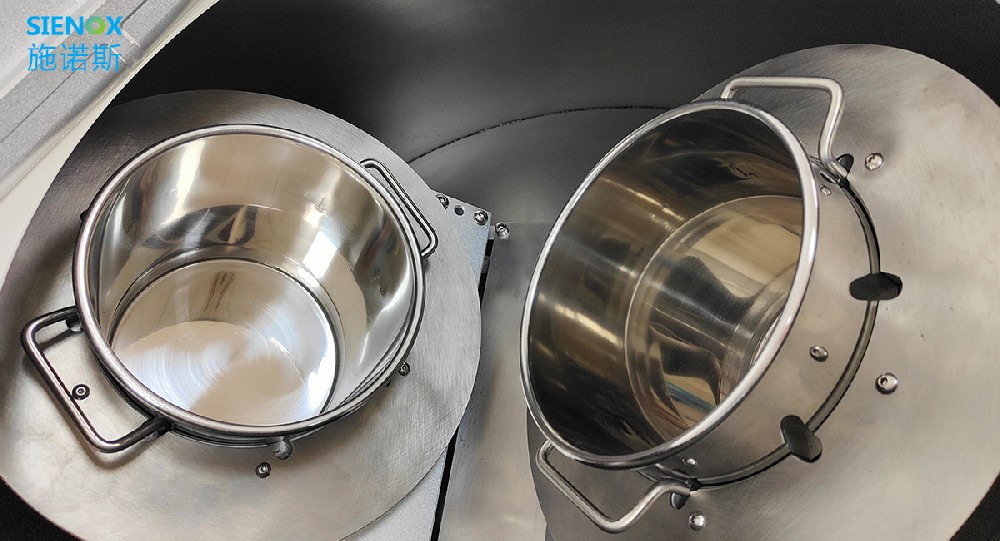

When using a planetary mixer, the appropriate container should be selected based on the required mixing capacity, and the equipment's rated capacity should be adhered to. Additionally, the appropriate speed should be selected based on the nature and requirements of the materials being mixed to ensure proper mixing effects and the normal operation of the equipment.

Feeding Sequence and Rate:

During operation of the planetary mixer, the correct feeding sequence and rate must be followed. Typically, liquid components should be added first, followed by solid components, to avoid uneven mixing and the risk of equipment blockage. The feeding rate should gradually increase to ensure uniform mixing.

Regular Maintenance:

Planetary mixers are precision equipment that requires regular maintenance to ensure their long-term stable operation. Regularly clean the equipment to prevent the accumulation of residues and the entry of impurities. Additionally, regularly inspect and replace vulnerable parts such as stirring blades and sealing rings to prolong the equipment's service life and maintain its efficient performance.

In summary, when using a planetary mixer, it's important to observe safety operations, conduct equipment inspections, adhere to appropriate capacity and speed guidelines, follow correct feeding sequences and rates, and perform regular maintenance. Only by strictly adhering to these considerations can we ensure the safe operation of the planetary mixer and achieve high-quality mixing effects.