News

TEL:18925129293

Bubble problem troubles? Fully automatic pressure defoaming machine easily solves the problem

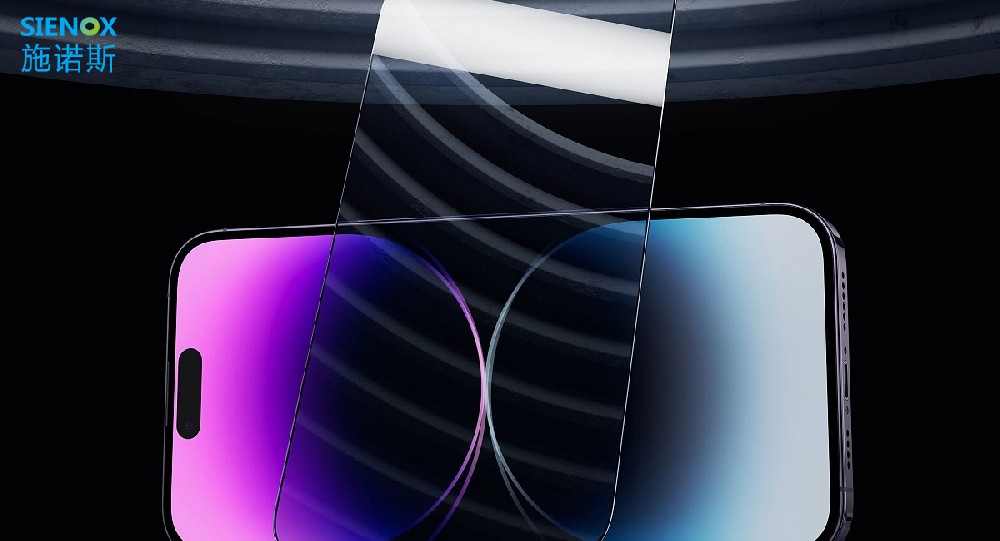

date:2023-09-04author:SIENOXIn the manufacturing industry, bubble issues have always been a headache. Especially in the production process of liquid crystal displays (LCD screens), precise lamination between the LCD screen and the substrate often leads to the generation of bubbles, affecting product quality and appearance. To address this problem, the fully automatic pressurized defoaming machine has emerged, which can easily solve the bubble problem and improve lamination effectiveness.

The fully automatic pressurized defoaming machine is an advanced device that utilizes an intelligent operating system and high-precision sensors to automatically control the pressurization and defoaming process. It is easy and convenient to operate: simply place the LCD screen and the substrate on the machine, set the pressurization time and pressure, and the machine will automatically perform the pressurization and defoaming operations. Through pressurization, bubbles are expelled, achieving a perfect lamination effect.

The fully automatic pressurized defoaming machine is not only suitable for LCD screen production but can also be widely used in the manufacturing processes of other electronic products. For example, electronic products such as mobile phones, tablets, and televisions all require lamination of LCD screens, and the emergence of the fully automatic pressurized defoaming machine has made the lamination process more efficient and accurate. It not only solves the bubble problem but also improves production efficiency and product quality.

The benefits of using a fully automatic pressurized defoaming machine are not only evident in solving bubble issues but also in saving production costs and time. Traditional lamination processes require manual operation and additional time and effort to repair bubbles. With the emergence of the fully automatic pressurized defoaming machine, the lamination process becomes more automated and intelligent, reducing labor costs and saving time.

Furthermore, the operation of the fully automatic pressurized defoaming machine is very safe and reliable. It uses high-precision sensors and control systems to monitor pressure changes in real-time during pressurization, ensuring stable and reliable lamination processes. Operators only need to set parameters, and the machine can automatically complete the pressurization and defoaming process, avoiding the risks associated with manual operation.

In summary, the fully automatic pressurized defoaming machine is a powerful tool for solving bubble issues. Its intelligent operating system and high-precision sensors make the lamination process simpler and more efficient. It is not only suitable for LCD screen production but also widely applicable in electronic product manufacturing. The emergence of the fully automatic pressurized defoaming machine not only solves the bubble problem but also improves production efficiency and product quality, bringing revolutionary changes to the manufacturing industry. Let's bid farewell to the hassle of bubble problems and effortlessly achieve perfect lamination!