News

TEL:18925129293

An essential tool for improving product quality: Analysis of the advantages of vacuum stirring and defoaming machines

date:2023-09-13author:SIENOXIn various industries, product quality is one of the key factors for enterprise development. As a device for removing bubbles from liquids, the vacuum stirring degassing machine has become an essential tool for enhancing product quality. So, what are the advantages of the vacuum stirring degassing machine compared to traditional stirring methods?

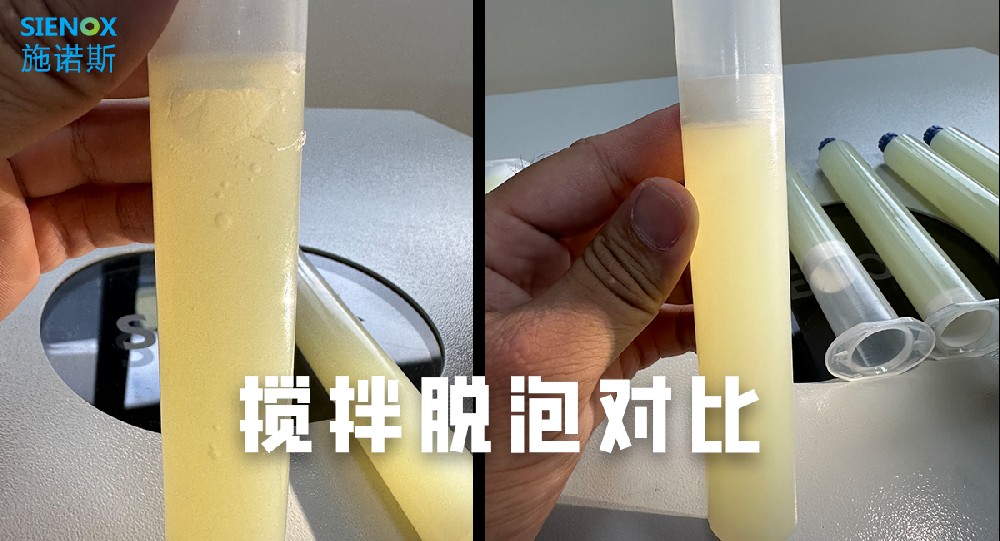

Firstly, the vacuum stirring degassing machine can more thoroughly remove bubbles. By reducing pressure, the solubility of bubbles in the liquid decreases, accelerating the process of bubble detachment. Compared to traditional mechanical stirring, the vacuum stirring degassing machine can more effectively remove bubbles, thereby improving product quality and stability.

Secondly, the vacuum stirring degassing machine can maintain the uniformity of the liquid. During the stirring process, the vacuum stirring degassing machine ensures thorough mixing of various components in the liquid, avoiding unevenness. This is particularly important for products that require precise control of component proportions, as it improves product consistency and stability.

Additionally, the vacuum stirring degassing machine can reduce foam production in products. In some products where foam production is desired, excessive bubbles can negatively impact product quality. The vacuum stirring degassing machine effectively removes bubbles, reducing foam production and enhancing the appearance and quality of the product.

In summary, as an essential tool for enhancing product quality, the vacuum stirring degassing machine offers advantages such as thorough bubble removal, maintenance of liquid uniformity, and reduction of foam production. These advantages have led to the widespread application of the vacuum stirring degassing machine across various industries as an important means of improving product quality.