Defoaming Mixer

TEL:18925129293

Top Quality Vacuum Planetary Centrifugal Stirring Mixing Mixer Optional Two 500ML Containers SIE-MIX650plus

◆ Dual cups, customizable capacity options

◆ Fixed planetary to rotation speed ratio

◆ 0-2000RPM, adjustable for experimentation based on material characteristics

◆ Vacuum/Cooling/Heating/MES system connectivity options available

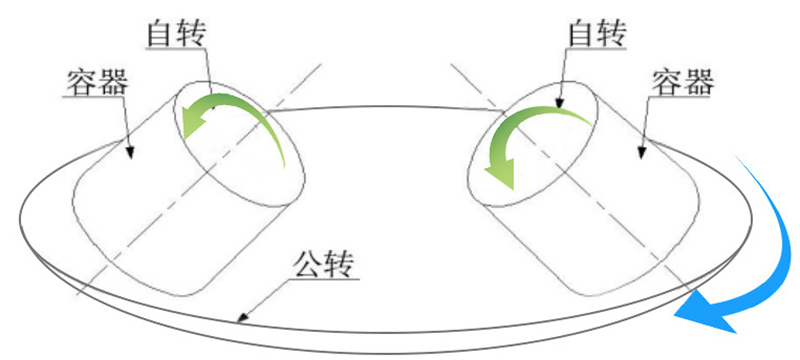

Working principle

By using the centrifugal force of revolution and the shear force of rotation to stir, coupled with a vacuum pump to extract gas, small bubbles in the liquid can be efficiently removed, improving product quality.

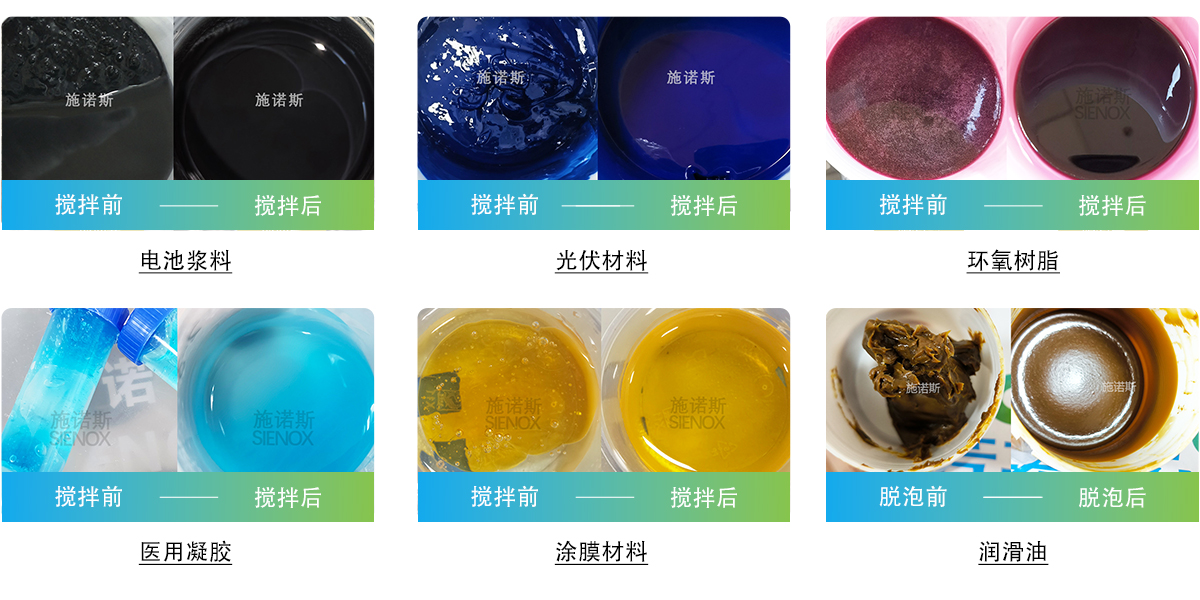

Comparison of Material Effects

Our equipment can be applied to various materials, including but not limited to fluorescent powders, adhesives, silicone gel, silver paste, aluminum paste, adhesives, inks, silver nanoparticles, silver nanowires, conductive silver paste, insulating adhesive, battery paste, etc. It can be stirred from liquid to solid, liquid to liquid, and solid to solid substances.

Only partial cases are displayed/materials are welcome to be brought to SIENOX for sample testing and machine testing

Product parameters table

Model | SIE-MIX650 | SIE-MIX650plus | SIE-MIX90 | SIE-MIXF1000 |

Speed(rpm) | 0-2000 | 0-2000 | 0-2000 | 0-2000 |

Time(min) | 1-30 | 1-30 | 1-30 | 1-30 |

Container | Tube/Can/Cup | Tube/Can/Cup | Tube/Can/Cup | Tube/Can/Cup |

Capacity (mL) | 0-500 | 0-500 | 0-1000 | 0-1100 |

Quantity | 1*2 | 1*2 | 1*2 | 1*2 |

Rotation speed ratio during revolution | fixed | fixed | fixed | Adjustable |

vacuum(kpa) | -98 | -98 | -98 | -98 |

Safety lock | Yes | Yes | Yes | Yes |

Refrigeration/Heating | Optional | Optional | Optional | Optional |

SEM function | Optional | Optional | Optional | Optional |

Size(cm) | 58*56*76 | 80*58*76 | 61*56*78 | 62*61*78 |

Weight(kg) | 145 | 170 | 153 | 170 |

***The above are just typical models, and we can provide personalized solutions according to customer needs.

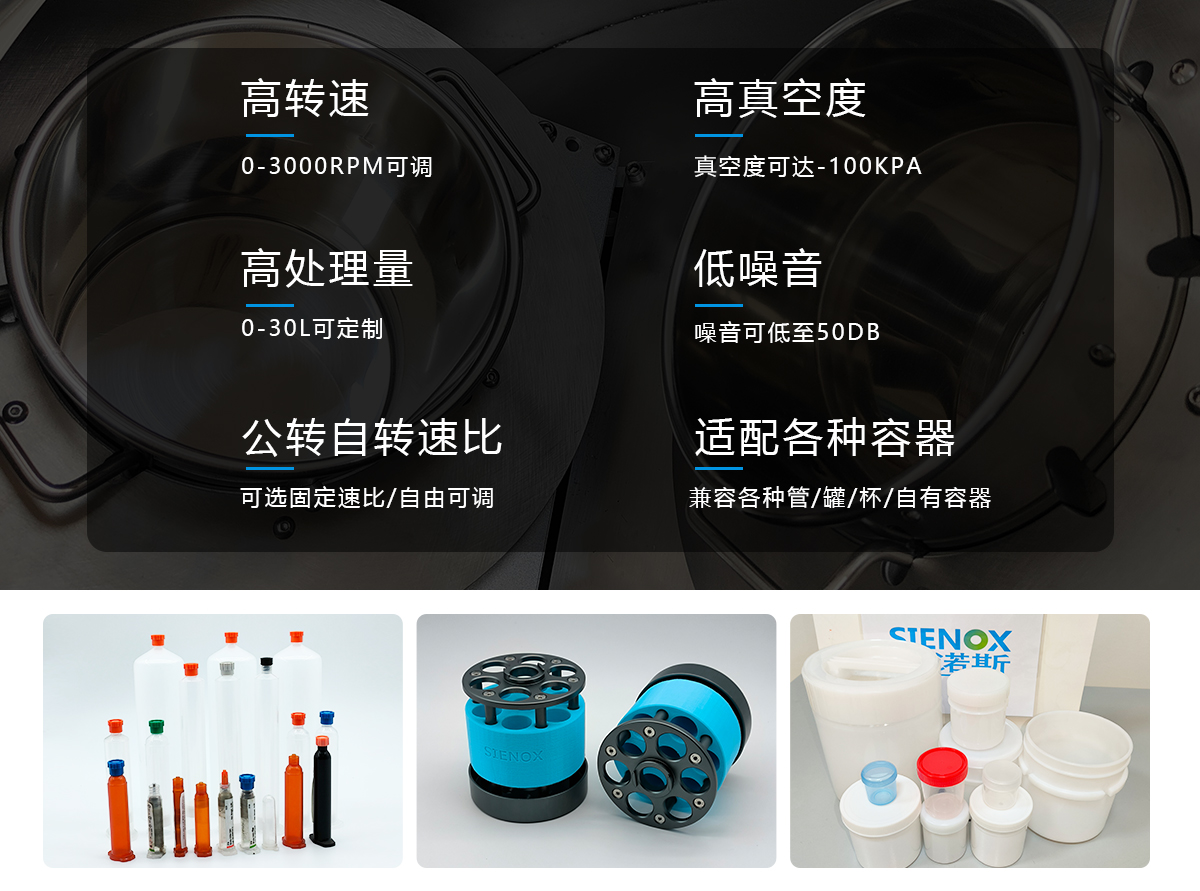

6 core advantages

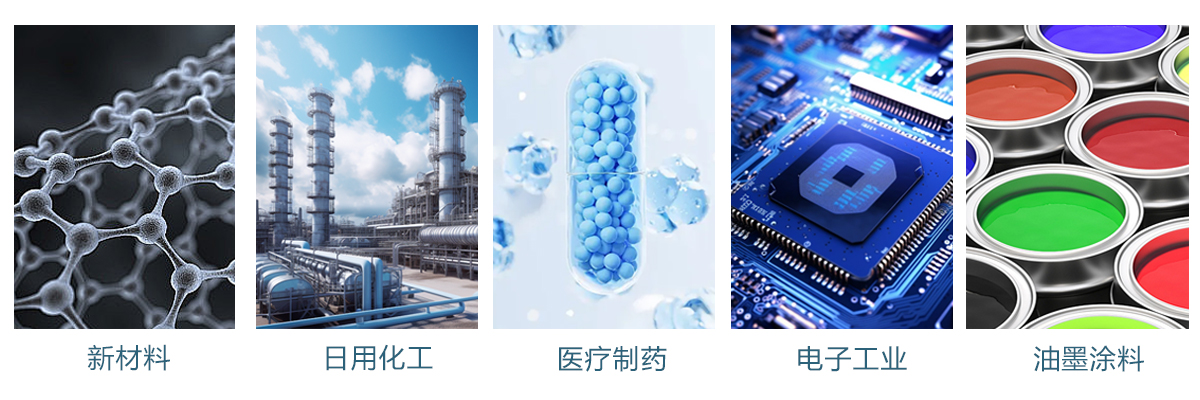

application area

Our cooperative clients

***Only partial successful customer information is displayed. We need more case studies and product selection materials. Please feel free to contact us

Sienox Defoaming Machine Product Selection Table

Model | SIE-MIX650 | SIE-MIX650plus | SIE-MIX90 | SIE-MIXF1000 |

Speed(rpm) | 0-2000 | 0-2000 | 0-2000 | 0-2000 |

Time(min) | 1-30 | 1-30 | 1-30 | 1-30 |

Container | Tube/Can/Cup | Tube/Can/Cup | Tube/Can/Cup | Tube/Can/Cup |

Capacity (mL) | 0-500 | 0-500 | 0-1000 | 0-1100 |

Quantity | 1*2 | 1*2 | 1*2 | 1*2 |

Rotation speed ratio during revolution | fixed | fixed | fixed | Adjustable |

vacuum(kpa) | -98 | -98 | -98 | -98 |

Safety lock | Yes | Yes | Yes | Yes |

Refrigeration/Heating | Optional | Optional | Optional | Optional |

SEM function | Optional | Optional | Optional | Optional |

Size(cm) | 58*56*76 | 80*58*76 | 61*56*78 | 62*61*78 |

Weight(kg) | 145 | 170 | 153 | 170 |

***The above are just typical models, and we can provide personalized solutions according to customer needs.

◆ Single cup/Dual cup options available

◆ Vacuum level up to -99kPa

◆ Can store up to 100 sets of operating parameters

◆ Multiple container options: tubes, tanks, and cups

◆ Non-contact design, does not alter the chemical properties of materials

◆ Planetary to rotation speed ratio options (fixed/adjustable)

◆ 0-3000RPM, adjustable for experimentation based on material characteristics

◆ High-speed mixing and defoaming in 1 minute, uniform mixing, eliminates nano-sized bubbles

◆ Customizable capacity, standard configurations include 300mL, 500mL, 1L, 2L, 5L, and 12L

◆ Uses imported components, body made of 304 stainless steel, durable and long-lasting

◆ Vacuum/Temperature control/MES system connectivity options available

◆ Aesthetically pleasing design, durable and robust

The vacuum defoaming mixer meets the mixing and defoaming needs for volumes ranging from 0 to 500 mL. Its adjustable planetary to rotational motion ensures clean and efficient mixing and defoaming. Customized services are offered to meet the diverse requirements of different customers. With a wide range of applications, the machine is aesthetically pleasing, durable, and robust.